IADR Abstract Archives

Merlon Test to Assess the Machinability of High-Performance Dental Polymers

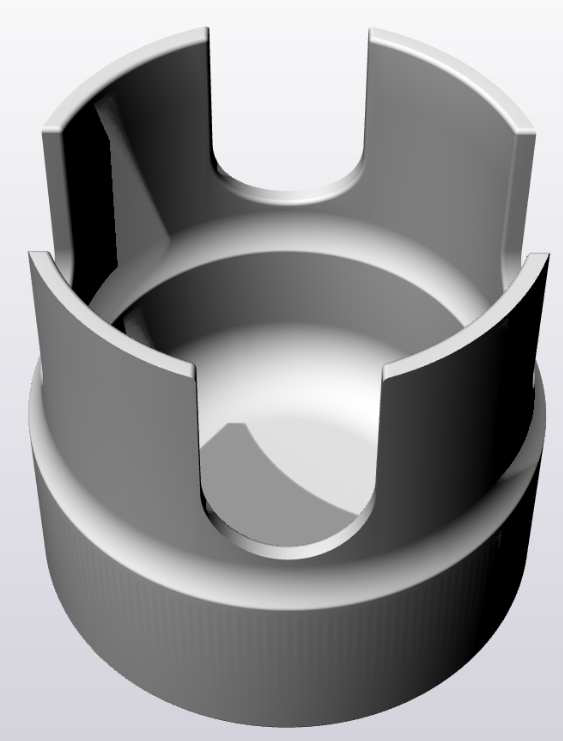

Objectives: A machinability test has been under analysis for use to evaluate ceramic materials. The merlon fracture test (ISO/TC 106/SC 9) was used to compare the machinability of two milled high-performance polymers (HPPs): a polyetheretherketone (PEEK) (JUVORA™ Dental Disc, Invibio), and a fiber-reinforced composite resin (FRC) (TRINIA™ CAD/CAM Disc, Trinia).

Methods: 3D designs of merlons with wall thickness 0.1mm, 0.2mm, 0.3mm, 0.4mm, and 0.5mm were obtained in STL format. 5 merlons of each thickness were milled from PEEK (JUVORA™ Dental Disc, Invibio) and FRC (TRINIA™ CAD/CAM Disc, Trinia) CAD/CAM Discs (Ø98mm) using the Dentsply-Sirona MC X5 5-axis milling unit and the Dentsply-Sirona inLab CAM 20.0.1 software. The resulting sample for each of the 10 groups was 20 walls and 5 bottoms per group. New tools were used for each disk. The sequence of machined specimens and machining errors were recorded. Specimens were digitally scanned, and intact merlons, walls, and bottoms were counted. Minimum machined thickness (MMT) was defined as the thickness at which 100% of specimens had intact walls and bottoms.

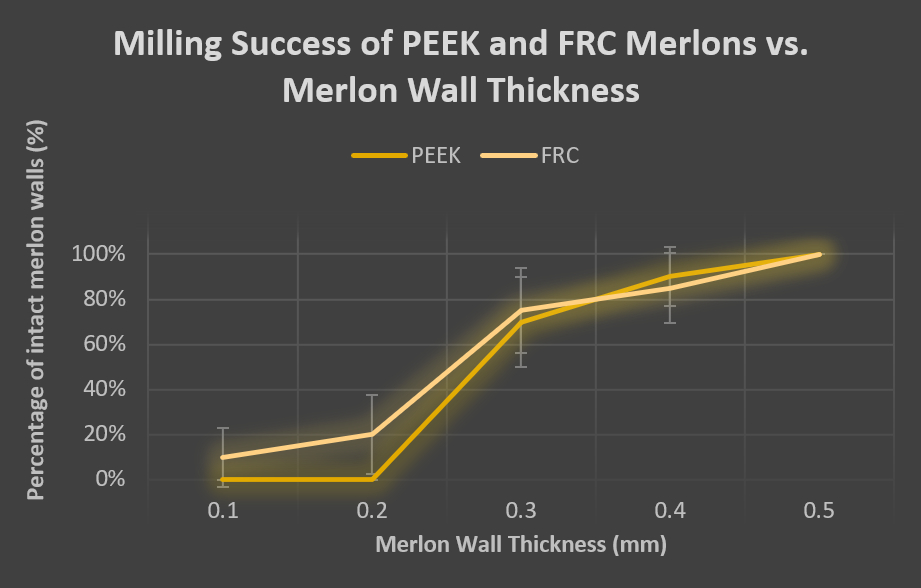

Results: None of the groups demonstrated any fractured bottoms. PEEK groups demonstrated 0% intact walls at 0.1mm and 0.2mm, 70% at 0.3mm (95% CI: 49.9-90.1%), 90% at 0.4mm (95% CI: 76.9-103.1%), and 100% at 0.5mm. FRC groups demonstrated 10% intact walls at 0.1mm (95% CI: -3.1-23.1%), 20% at 0.2mm (95% CI: 2.5-37.5%), 75% at 0.3mm (95% CI: 56.0-94.0%), 85% at 0.4mm (95% CI: 69.4-100.6%), and 100% at 0.5mm. FRC manufacturing was interrupted due to worn down tools twice per disc.

Conclusions: Within the limitations of this study, MMT of 0.5mm is recommended for both PEEK and FRC according to the Merlon Fracture Test. Machining of FRC may be more expensive and time-consuming than that of PEEK due to the need for diamond-coated tooling and the higher tool replacement rate.

Methods: 3D designs of merlons with wall thickness 0.1mm, 0.2mm, 0.3mm, 0.4mm, and 0.5mm were obtained in STL format. 5 merlons of each thickness were milled from PEEK (JUVORA™ Dental Disc, Invibio) and FRC (TRINIA™ CAD/CAM Disc, Trinia) CAD/CAM Discs (Ø98mm) using the Dentsply-Sirona MC X5 5-axis milling unit and the Dentsply-Sirona inLab CAM 20.0.1 software. The resulting sample for each of the 10 groups was 20 walls and 5 bottoms per group. New tools were used for each disk. The sequence of machined specimens and machining errors were recorded. Specimens were digitally scanned, and intact merlons, walls, and bottoms were counted. Minimum machined thickness (MMT) was defined as the thickness at which 100% of specimens had intact walls and bottoms.

Results: None of the groups demonstrated any fractured bottoms. PEEK groups demonstrated 0% intact walls at 0.1mm and 0.2mm, 70% at 0.3mm (95% CI: 49.9-90.1%), 90% at 0.4mm (95% CI: 76.9-103.1%), and 100% at 0.5mm. FRC groups demonstrated 10% intact walls at 0.1mm (95% CI: -3.1-23.1%), 20% at 0.2mm (95% CI: 2.5-37.5%), 75% at 0.3mm (95% CI: 56.0-94.0%), 85% at 0.4mm (95% CI: 69.4-100.6%), and 100% at 0.5mm. FRC manufacturing was interrupted due to worn down tools twice per disc.

Conclusions: Within the limitations of this study, MMT of 0.5mm is recommended for both PEEK and FRC according to the Merlon Fracture Test. Machining of FRC may be more expensive and time-consuming than that of PEEK due to the need for diamond-coated tooling and the higher tool replacement rate.